Clean Equipment is Resilient Equipment

In industries such as construction, oil exploration, and agriculture, to name a few, equipment reliability and longevity are paramount. For operators and maintenance teams, safeguarding their equipment against the elements and ensuring peak performance is essential to the success of their operations. Dirt, mud, oil, grease, grime, and other contaminants can wreak havoc on both the appearance and functionality of all types of machinery and equipment.

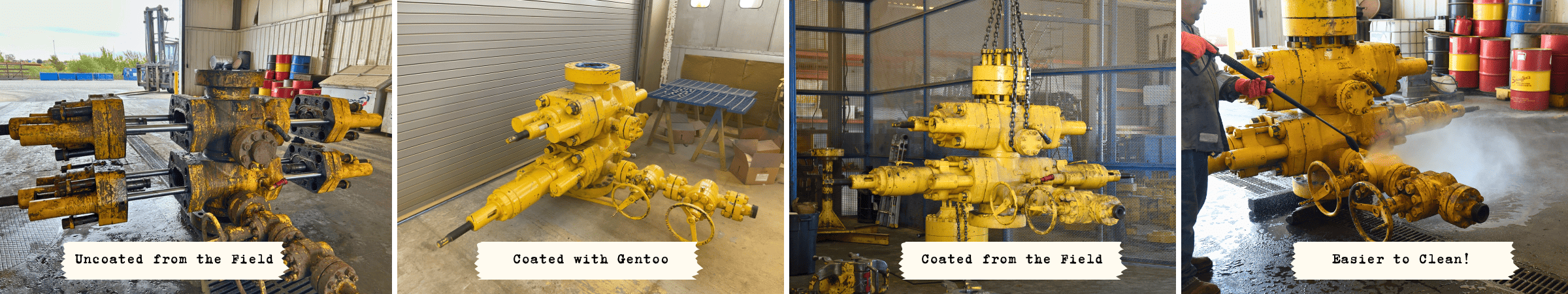

Gentoo creates an organic, clear, and durable hydrophobic and oleophobic barrier that repels common contaminants that plague equipment operating in less-than-ideal conditions. It can also stand up to even the harshest of environments—hot, cold, wet, or dry. This equates to less wear and tear, fewer breakdowns, and a longer operational life. For businesses, this means less downtime, fewer cleaning expenses, and extended periods between replacing equipment. When thicker or heavier contaminants do happen to stick to machinery or equipment, Gentoo makes that stuff easier to clean, oftentimes cutting wash times by 75% or better.

“Cleaning a single BOP [blow-out preventer] used to require an hour or more. With Gentoo-coated BOPs, we’re down to about 15 minutes—and that translates directly into savings.” – Great Plains Oilfield Rental

Gentoo’s applications extend beyond construction, oil exploration, and agriculture. Not only does it create an easy-clean protective barrier, but it’s also an amazing anti-corrosive coating, making it especially useful in marine settings, where equipment and gear often face a barrage of salt and water (which drastically accelerates corrosion). And since Gentoo is transparent, it makes for a great protective layer between the elements and glass. In fact, Gentoo has been used by the U.S. military to coat F16 canopies, where visibility is obviously crucial.

Applying Gentoo is a straightforward process. The initial preparation involves ensuring that the surface is clean and devoid of any contaminants. Depending on the specific needs and the equipment at hand, Gentoo can be applied using dip coating, brushing, or spraying techniques. Each method is designed to ensure even coverage and optimal adherence to the surface. While the application process is simple, it’s essential to follow the recommended guidelines to achieve the best results and ensure the coating’s effectiveness over time. Once applied, Gentoo forms a lasting barrier that offers robust protection against harsh environments and contaminants.