Flexibility

Initial flexibility assessment is performed using a mandrel bend test where coated metal coupons are bent around mandrels ranging in diameter from 1/8 to 1 inch and assessed for cracking or delamination from the substrate according to ASTM D522. Bend Adhesion testing as specified in MIL-PRF-85285 to evaluate cold temperature flexibility of the Gentoo at -51°C is also performed.

Initial flexibility assessment is performed using a mandrel bend test where coated metal coupons are bent around mandrels ranging in diameter from 1/8 to 1 inch and assessed for cracking or delamination from the substrate according to ASTM D522. Bend Adhesion testing as specified in MIL-PRF-85285 to evaluate cold temperature flexibility of the Gentoo at -51°C is also performed.

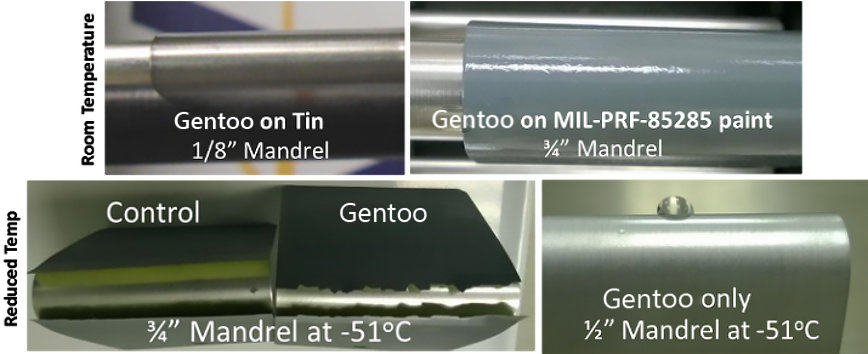

Gentoo exhibits excellent flexibility at room and low temperatures (Figure 2). Gentoo at -51°C bent over a ¾ inch mandrel cracked during low temperature flexibility assessment, but failure of the primer – aluminum panel interface resulted in complete coating failure.

Gentoo was not the source of the failure and the ragged edges are indicative of Gentoo attempting to keep the coating system together despite the delamination event. An aluminum panel coated only with Gentoo was reevaluated at -51°C and passed ½ inch mandrel bend. Hydrophobic performance of the Gentoo retained as evident by the water drop on the tested surface.

Figure 2: Mandrel Bend Flexibility of Gentoo Treatment at Room Temperature direct to metal and on MIL-PRF-85285 grey urethane topcoat (Top Row) and -51°C on MIL-PRF-85285 grey urethane topcoat (Bottom Row)

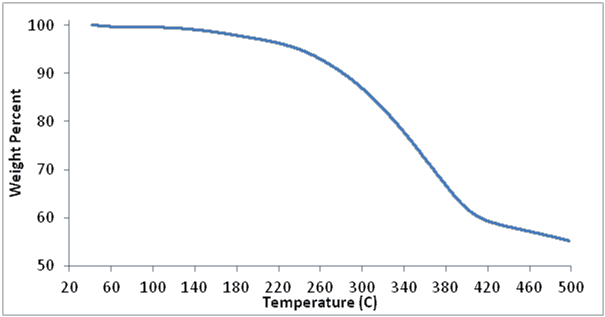

Gentoo is stable up to 200°C according to Figure 3 TGA decomposition curve. Thus, the coating has a wide range of operating temperatures from -51 to 200°C.; however, for continuous use (as opposed to temperature spikes) we recommend a maximum operating temperature of 160°C

Figure 3: TGA of cured, Gentoo formulation (ramp rate of 3°C/minutes)