Chemical Resistance

Gentoo was also assessed for fluid resistance when applied over MIL-PRF-23377 epoxy primer with MIL-PRF-85285D grey urethane topcoat painted, LHE Zn-Ni plated 4130 steel panels according to MIL-PRF-85285D fluid immersion testing and the High-strength Steel Joint Test Protocol. For MIL-PRF-85285D fluid immersion testing, coated panels are cured, stored in a desiccator for at least 16 h, and weighed prior to immersion in the following solvents for 7 days at 37.8°C: Aircraft Deicing/Anti-icing fluid (SAE AMS 1424), Cleaning Compound (Degreaser), Aerospace Equipment (MIL-PRF-87937) and Paint Remover, PR-3500 epoxy paint remover.

| Immersion Fluid | Fluid Temperature | Time of Immersion |

|---|---|---|

| Lubricating oil (conforming to MIL-L-23699) | 121 ±3 °C (250 ±5 °F) | 24 hours |

| Hydraulic fluid (conforming to MIL-PRF-83282) | 66 ±3 °C (150 ±5 °F) | 24 hours |

| JP-8 fuel (conforming to MIL-DTL-5624) | Room temperature | 7 days |

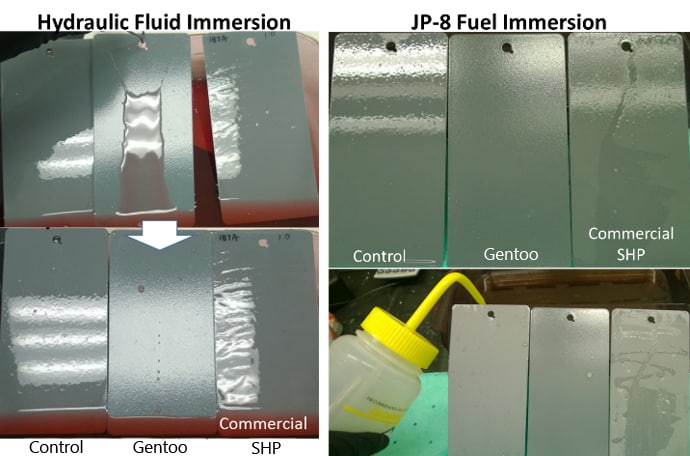

Gentoo demonstrated no blistering or coating defects and maintained hydrophobic performance following immersion in aircraft deicing fluid, cleaning compound (degreaser), lubricating oil, hydraulic fluid and JP-8 fuel. The Gentoo was removed using the PR-3500 epoxy paint remover, as expected. Commercially available superhydrophobic (SHP) paint was also assessed, and that coating lost all superhydrophobic and hydrophobic performance after immersion in all fluids, and was completely removed when immersed in most fluids, except deicing fluids. Figure 1 exhibits some representative images.

Figure 1: Fluid Immersion assessment of MIL-PRF-23377 Primer with MIL-PRF-85285D Topcoat painted aluminum panels untreated (control), Gentoo-treated, and commercial SHP treated in Hydraulic fluid at 66°C for 24 hours(Left) and JP-8 at room temperature for 7 days followed by an isopropanol rinse (Right)