Barrier Properties & Galvanic Corrosion Resistance

Electrochemical Impedance Spectroscopy (EIS) was used to evaluate the barrier properties of the Gentoo coating. Aluminum alloy UNSA92024 coupons were coated with MIL-PRF-85285D grey polyurethane (1.0 mil thick) and tested with and without the addition of Gentoo.

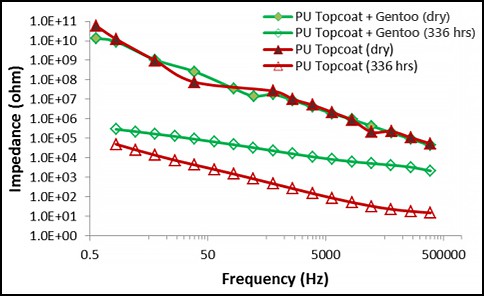

Initial testing (i.e. “dry”) of the samples showed similar impedance across the full frequency range (Figure 4). After exposure to ASTM B117 salt fog conditions for 336 hours, the samples were retested. The polyurethane only sample showed a significantly larger reduction in impedance (~two decades) compared to the Gentoo, indicating significantly better barrier properties for the coupon.

Figure 4: Electrochemical Impedance Spectroscopy (EIS) testing – MIL-PRF-85285D Polyurethane coated UNSA92024 aluminum.

Galvanic corrosion around cathodic fasteners mated to anodic aluminum alloy structures is a common problem in the aircraft community. It is known that galvanic corrosion of aluminum is controlled by the available cathodic current, and that a reduction in available current should result in less corrosion damage.